The most fatal shortcomings of LED lamps: LED lumen attenuation

The most fatal shortcomings of LED lamps: LED lumen attenuation

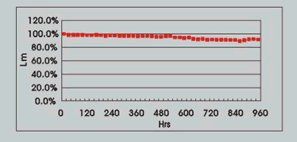

LED lights has now become the mainstream lighting equipment, but LED lights have a problem, you will find your LED lamps will be dark with the use of time, may be the second year only 90% of the beginning, the third year Only 80%, and the fourth year…… LED has a lot of incomparable advantages: energy saving, environmental friendly, long service life, etc.. LED-related lighting fixtures received more and more attentions of consumers and producers. But LED light attenuation is also a big problem for LED manufacturers, which must be solved. Fast light attention impact the service life of LED lamps. Now, engineers faced bottlenecks in this area. MINSENS TECH have been committed to reduce LED light attenuation.

Ⅰ The quality of the LED product itself

1. The brightness of LED will attenuate quickly if the quality of the adopted LED chip is not good.

2. The production technology has some defects. If the heat generated by LED chips can not be exported out of the chip smoothly by the PINs, LED chips may be over heated and thus causing chip attenuation more serious.

Ⅱ The operating condition

1. LED should be drove by constant current, if drove by voltage, LED lumen attenuation will be caused.

2. If the driving current is larger than the rated value, LED lumen may easily get attenuated.

Among the various causes of LED products lumen attenuation, “heat” is the pivotal one. Many manufacturers pay little attention to the heat dissipation of the products, leading to a much more serious lumen attenuation compared to those products that dissipate heat properly. Besides, thermal resistance of the LED chip itself, silver colloid, the heat dissipation effect of the substrate and golden wire problems are also related closely to LED lumen attenuation.

There are a variety of reasons may lead to LED light attenuation, heat dissipation is the most critical problem. Although many LED manufacturers spent a lot of energy and money on the secondary products (LED modules, LED applications), they still cannot maintain normal working conditions for a long time. The light attenuation of these secondary products is more serious than products with good cooling solutions. LED light attenuation has closed relations with the thermal resistance of LED chips, influences from silver plastics, the cooling effect of substrates, colloids and gold wires.

The quality of white-ray LED lamps can be said that a rather important factor for light attenuation. For example, same crystal 14mil white-ray LED chip: if using ordinary epoxy as bottom glue, packaging together with white glue and packaging glue, after 1000-hour constant working in 30 centigrade, the light attenuation is about 70%; if using D-type packaging glue, after 1000-hour constant working in 30 centigrade, the light attenuation is around 45%; if using C-type packaging glue, the light attenuation is only 12%; if using B-type packaging glue, the light attenuation is -3% (brighter than original products); if using A-type packaging glue, the light attenuation is -6% (even better).